Home >> Service >> Technical support

DPI series intelligent measuring instrument for high temperature measurement of distillation machine |

Abstract: from three aspects of sensitive components, pressure transmitter and structure, this paper briefly introduces the composition of DPI series intelligent measuring instruments, and expounds the problems that should be paid attention to during installation, which have wide application value. Key words: DPI; Intelligent measuring instrument; Sensitive components; Pressure transmitter 0 Introduction With the implementation of the new GMP New Deal in China, the new standards are more stringent in all aspects. At present, manufacturers of multi-effect distillation dispensers in China can not be separated from the data collection of pressure, liquid level, temperature, flow rate, conductivity, and pH meters in the process of control of distillation dispensers. According to the signals collected by a meter, water quality and production can be controlled. Ensure production safety, stability and reliability. At present, the DPI series instruments developed by Baoji Pepsi have been reliably applied to pharmaceutical equipment for a long time. They are mainly used for the pressure, liquid level, and temperature detection of distilled water dispensers, especially the newly developed DPI41 high temperature pressure transmitter. The Silicon sensor can not solve the problem of measuring high temperature. 1 Composition of DPI series intelligent measuring instruments DPI series intelligent measuring instruments mainly consist of 3 parts. 1.1 Part I: Sensitive Components Sensitive components(Fig. 1) use BAISSDE aviation-grade pressure and temperature sensitive originals, strict manufacturing process control, use of high temperature, high pressure, high insulation materials to ensure the reliability and stability of the product. Sensitive components are also key parts of measuring instruments. They are composed of precision mechanical coordination, semiconductors, and a variety of material packages(Silicon crystals, glass, ceramics, gold wires, stainless steel, high-temperature sintering, filled Silicon oil, thick film resistors, special adhesives, etc.). The sensor has the characteristics of linearity, low temperature drift and high stability.

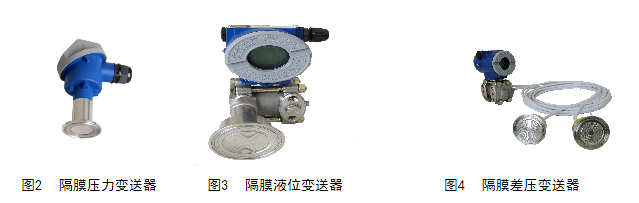

Figure 1 Sensitive Components Among them, Honeywell Corporation, USA, was the first successful silicon sensor in the world. At that time, silicon crystals were used as basic materials for experimental use. Each silicon sensor can only be used once, and the cost is very high. With the improvement of industrial automation level, more and more primary instruments are needed in related industries. Therefore, BAISSDE, IC, Lova and Foxboro ICT in the United States protect and package silicon crystals and develop silicon sensitive components that can be reused for a long time. Through tens of thousands of tests and 30 years, they can be used repeatedly. Continuous improvement has been able to provide long-term stable and reliable operation of silicon sensitive components. However, there are still two shortcomings of silicon sensitive components: (1) overload can only be 1.5 times (range overload, i.e. pressure, liquid level; (2) the range of temperature is limited and can only work between - 25 ~85 (?) By improving the silicon base material, Baoji PepsiCo has increased the overload performance to 6 times, and the temperature range without external mechanical structure can be increased to 150 C, which is suitable for more different environmental conditions. 1.2 Part II: Pressure transmitters Sensitive components can not be used in the industrial process, it is only a component, which needs to be converted into a product. The pressure transmitter designed by PepsiCo adopts different testing methods. After reasonable arrangement and screening of electronic components, the data of circuit and sensitive components can be collected, and data analysis, data correction, forward and backward protection can be carried out. The non-standard signal output by sensitive components can be converted into acceptable DC analog quantity electricity. Signal mA for easy transmission to control room or display device. Diaphragm pressure transmitter, diaphragm level transmitter and diaphragm pressure transmitter are shown in figs. 2, 3 and 4 respectively.

Pressure transmitter has the following characteristics: (1) Adjust the different performance of sensitive components, so that each standard signal output transmitter should be normalized to achieve measurement accuracy. (2) Long-term and safe use. 1.3 Part III: Structure According to GMP requirement, the material of the structure part of the measuring instrument should conform to the production standard. The measuring instrument produced by PepsiCo has flat diaphragm, no dead angle, 316L stainless steel for liquid connection, 304 stainless steel for outer sleeve, cast aluminium alloy for electronic cavity, and IP66 sanitary grade protection. The structure of the measuring instrument has the following characteristics: (1) After the electrical connection is tightened, ensure the normal operation of the transmitter in spraying, dust, short-term flooding and other environments, fully in line with GMP requirements. (2) Individualized scheme design can be carried out according to different needs of customers, including product structure and product characteristics.

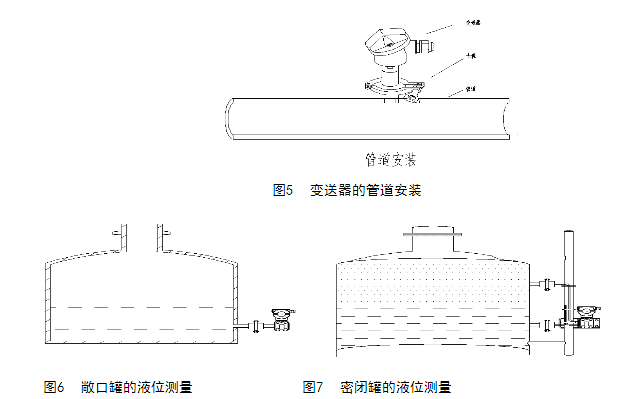

2 Installation Environment DPI series instruments specific use conditions and environment need to communicate with users in detail. In the process of installation, attention should also be paid to process pressure and limit pressure. The installation of measuring instruments is shown in Figure 5. In many systems, especially in hydraulic pressure measurement and processing, there are peaks and continuous irregular fluctuations, which can easily lead to higher overload pressure. The transmitter is damaged by impact, but it can not be detected in appearance. Therefore, the limit pressure can not be ignored in the selection of type. In the selection of distillers whose inlet pressure temperature is higher than outlet pressure temperature, it is necessary to mark the temperature range so as not to damage the resistance bridge arm on silicon crystal or even the transmitter.

The liquid level measurements of open and closed tanks are shown in figs. 6 and 7, respectively.

Baoji PepsiCo DPI series instruments have been used in pharmaceutical equipment for a long time and reliably. They are mainly used in the pressure, liquid level and temperature detection of distillers. The newly developed DPI 41 high temperature pressure transmitter fundamentally solves the problem that silicon sensors can't measure high temperature, and has popularization value. In addition, the pressure and temperature on-line measuring instrument is also widely used in the monitoring of the production process of food, beverage, wine and dairy products, which solves the problems of high temperature disinfection, anti-overload, no dead angle and so on. The product has also obtained domestic patents.

|